0086 15335008985

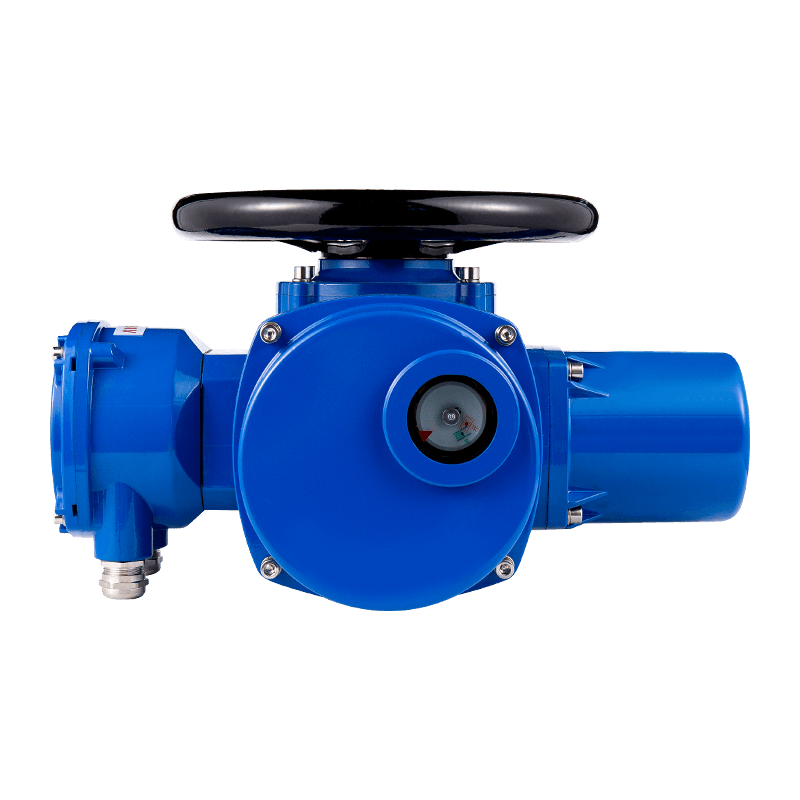

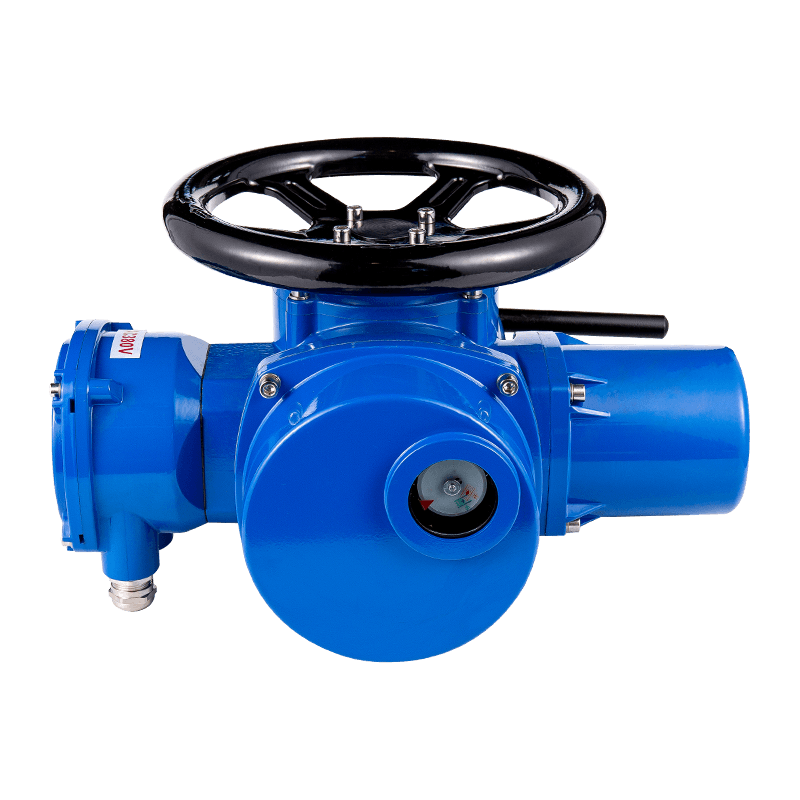

Overview

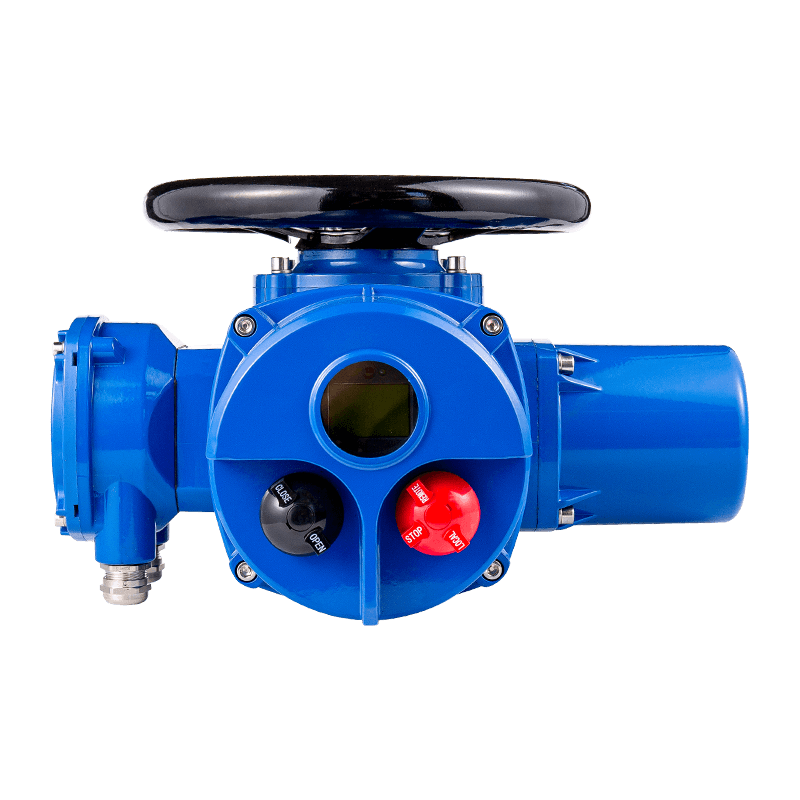

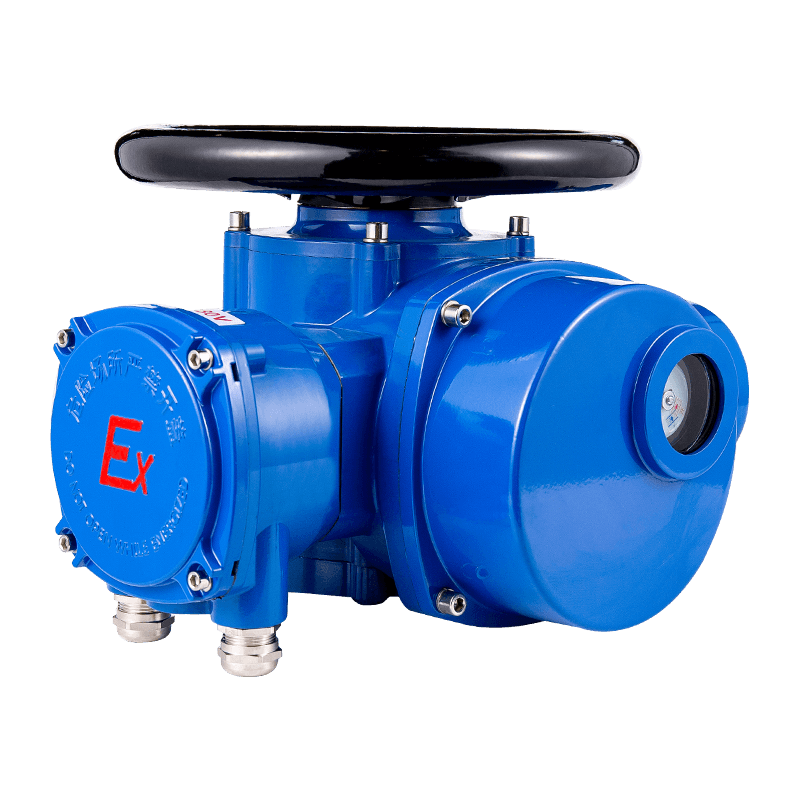

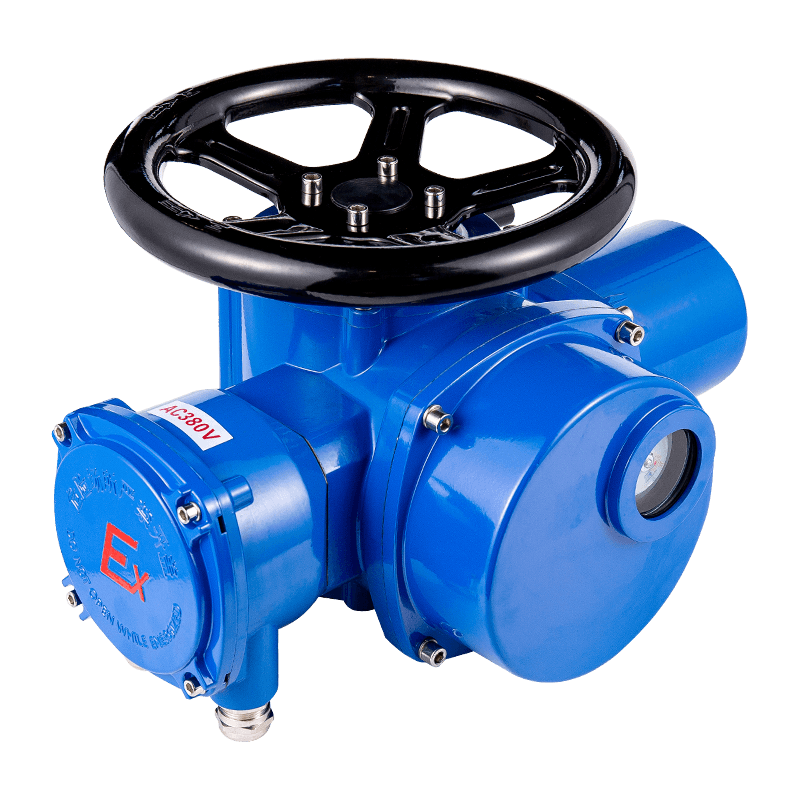

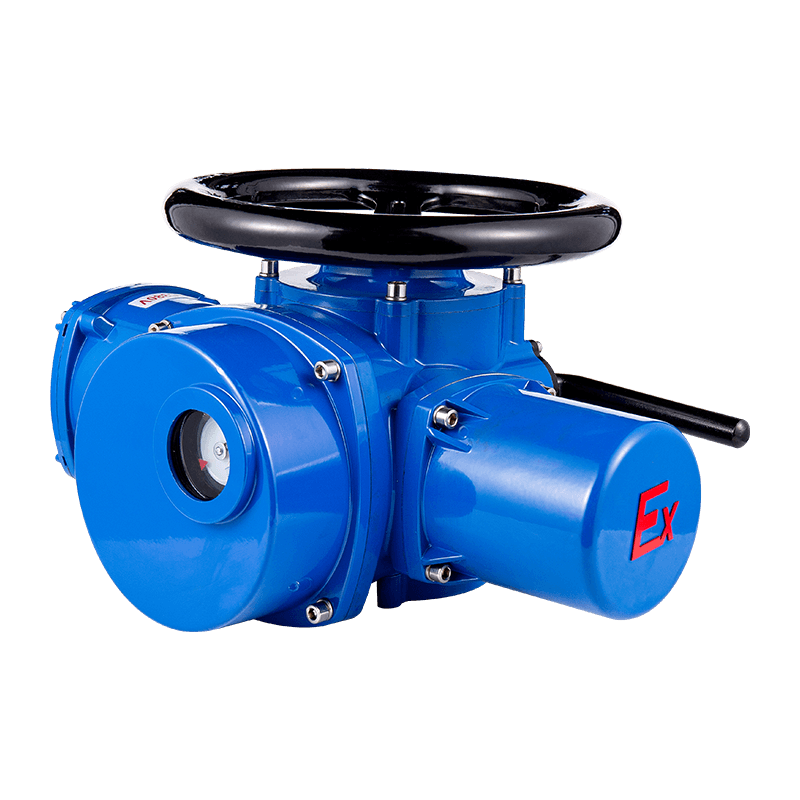

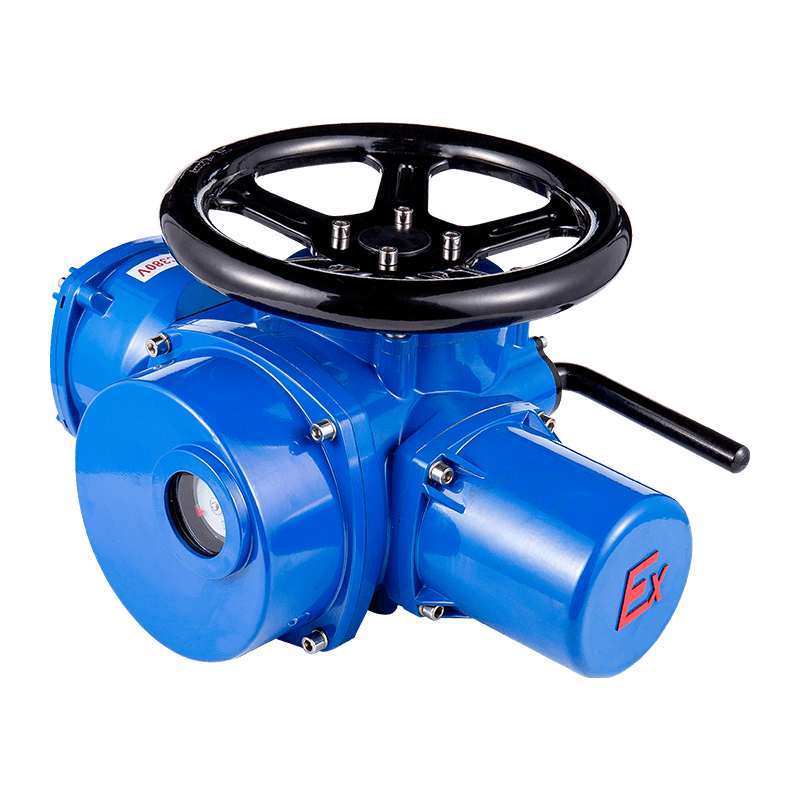

ZL series multi-turn valve electric actuator is an improved and perfected structure based on the original mature products, with optimized protection performance and key components. It is a driving device that realizes intelligent opening, closing and regulating control of valves. This series of actuators has the characteristics of full functions, reliable performance, advanced control system, small size, lightweight, easy use and maintenance, etc.

ZL series actuators are suitable for valves with linear motion of opening and closing parts, such as gate valves, stop valves, diaphragm valves, plunger valves, intercept valves, sluice gates, etc. They can be used for rising stem valves and concealed stem valves. When matched with turbine boxes, they can be used for ball valves, butterfly valves and dampers, etc. They can perform local control, remote control and automatic control on valves, and are widely used in industries such as electricity, metallurgy, petroleum, chemical industry, pharmaceuticals, water services, and agricultural irrigation.

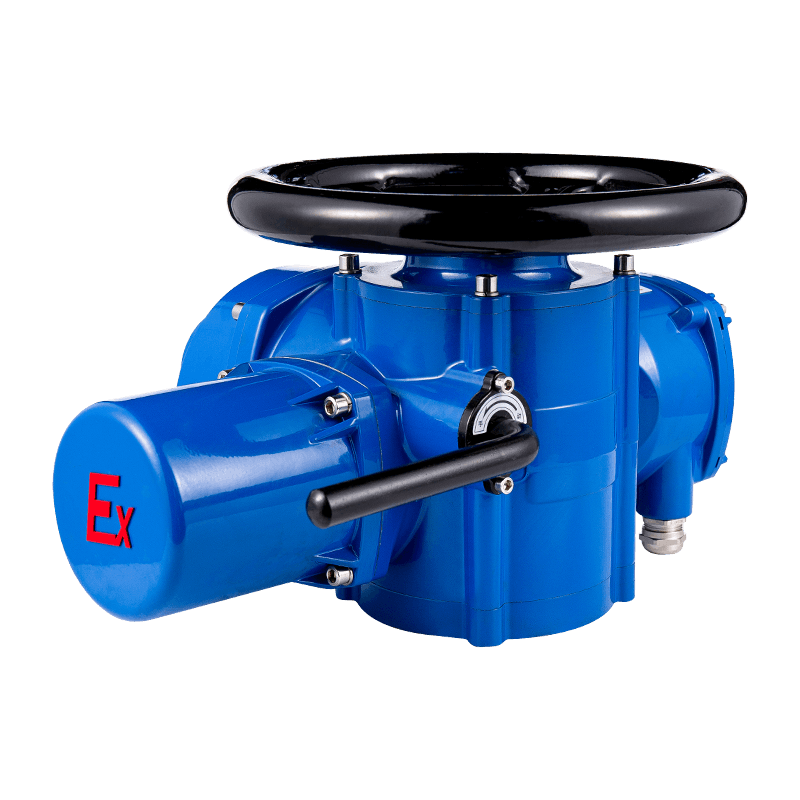

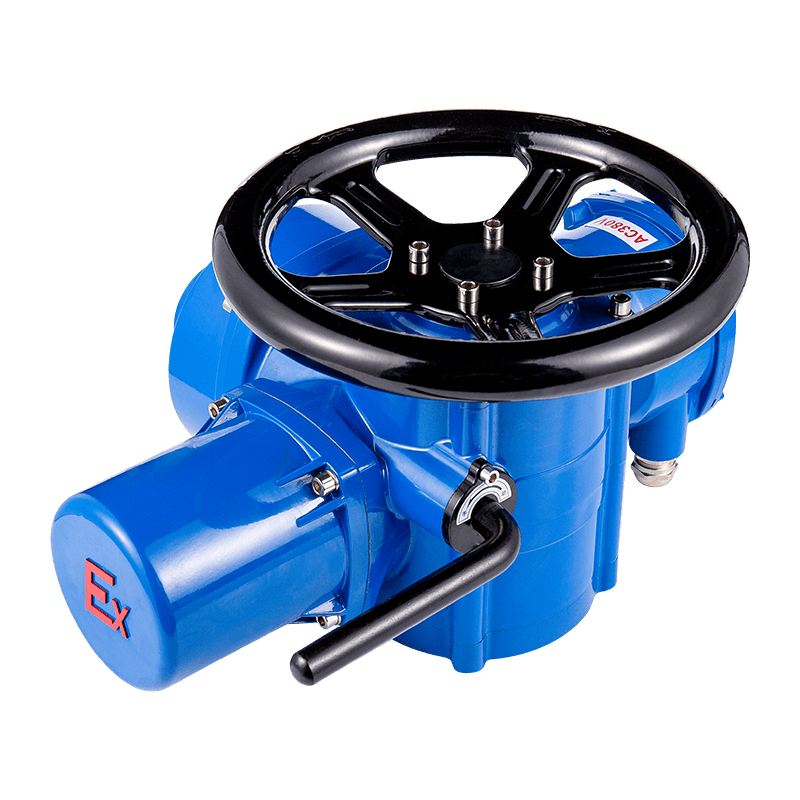

Classification

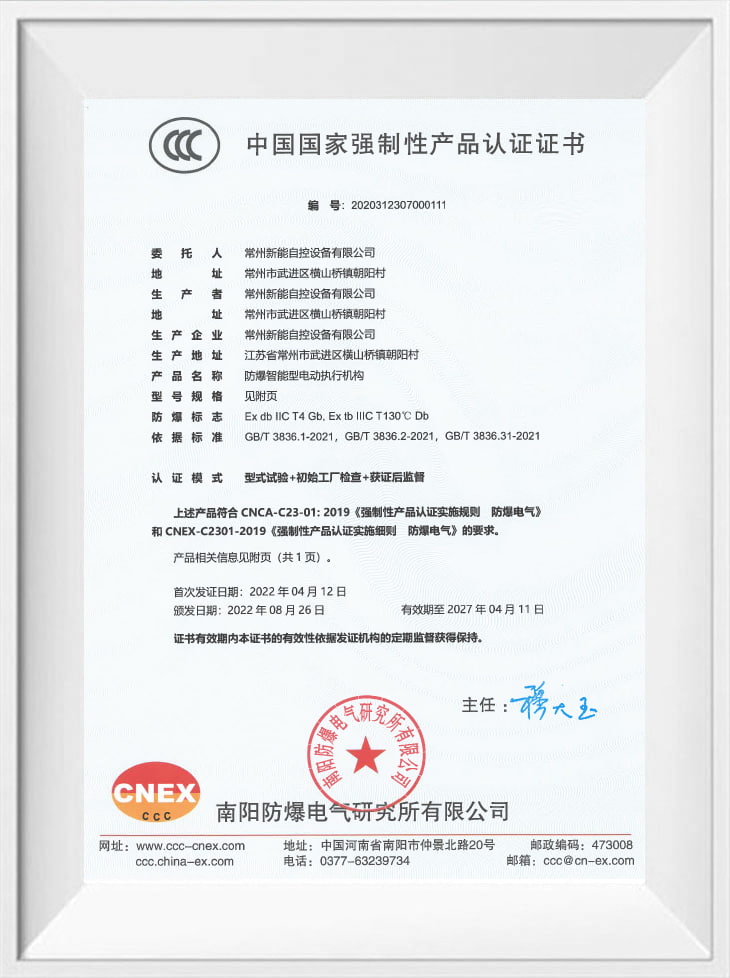

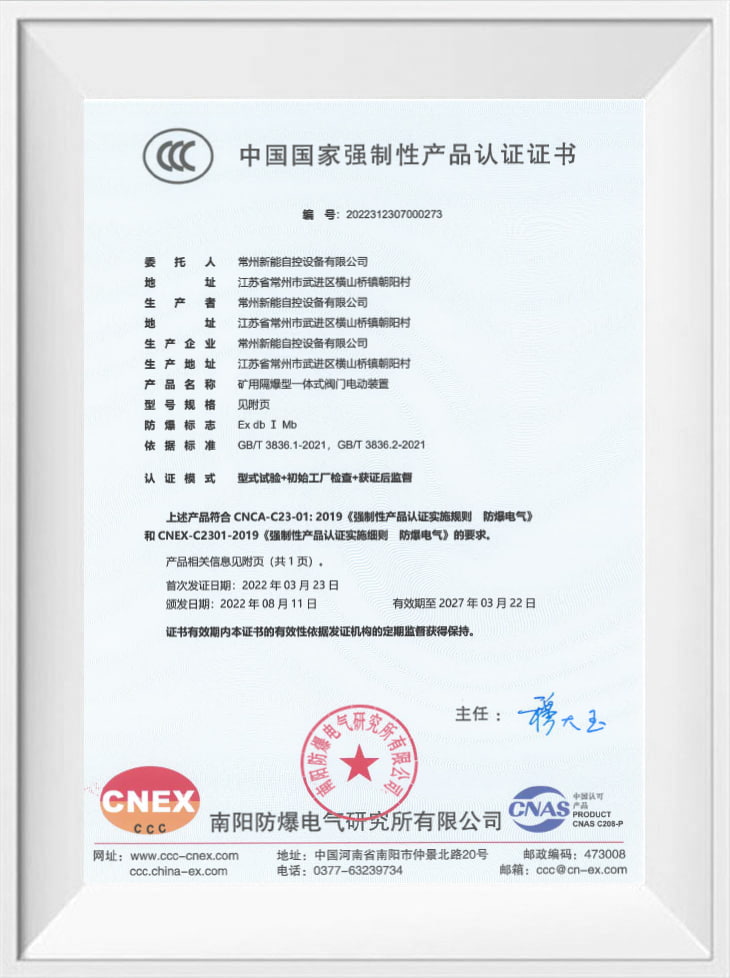

Basic type, intelligent type, explosion-proof basic type, explosion-proof intelligent type.

Working environment and main technical conditions

(1) Power supply: three-phase AC380V, 50Hz;

Optional power supply: three-phase AC400V, 415V, 660V (50Hz, 60Hz)

Single-phase AC220V, 110V (50HZ, 60HZ)

DC24V,48V,84V

(2) Ambient temperature: -20℃~+60℃; Optional temperature: -40℃~+70℃

(3) Relative humidity: no more than 95% (at 25°C)

(4) Working environment: The ordinary type is used in places without flammable, explosive and highly corrosive media; the flameproof type (ExdIIBT4) is used in environments of IIA,

Explosive gas mixtures of class IIB, groups T1-T4

(5) Protection level: IP65, IP67 (IP68 for special order)

(6) The motor is of short-time duty type: rated operating time is 10 minutes (15-30 minutes for special orders), and Class F insulation.

(7) Anti-corrosion coating: high-temperature electrostatic spray anti-corrosion epoxy plastic powder

(8) Main functional features of intelligent electric actuators

Mechatronic design, small size, and lightweight

It adopts a digital integrated chip, with powerful functions and high precision.

With a non-intrusive design, parameter setting and debugging can be done through knobs or infrared remote control without opening the box cover. The operation is simple and fast, and the sealing is higher.

The stroke displacement adopts an absolute encoder, the valve position will not be lost, the anti-interference ability is strong, the accuracy is higher, and the service life is long.

The LCD subtitles are available in Chinese or English.

It has functions such as travel limit protection, torque protection, stall alarm, overheat protection, signal failure protection, power phase loss protection, and automatic phase sequence identification and correction.

Intelligent types include intelligent switch type, intelligent adjustment type, and advanced intelligent type.

(9) Intelligent switch type input signal: 24VDC pulse or level signal.

Output signal: relay output, contact rated capacity: 5A, 250VAC, 5A, 30VDC.

Output position analog signal: 4-20mA

Intelligent regulation analog input signal: 4-20mA

Analog output signal: 4-20mA

Switch input signal: 24VDC pulse or level signal.

Switching output signal: relay output, contact rated capacity: 5A, 250VAC, 5A, 30VDC.

Basic error: ≤1

The advanced intelligent type can support ESD emergency override protection, bus communication, Bluetooth, wireless control and other functions.

Model specifications and performance parameters

|

Model |

Nominal torque Nm |

Output speed r/min |

Output shaft setting the number of revolutions (turns) |

Motor power (KW) |

Manual Speed Ratio |

Maximum stem diameter (mm) |

Reference weight (kg) |

|

ZL5 |

50 |

18 |

180 |

0.12 |

1:1 |

30 |

20 |

|

ZL10 |

100 |

18 |

180 |

0.18 |

1:1 |

30 |

20 |

|

24 |

180 |

0.25 |

1:1 |

30 |

20 |

||

|

36 |

180 |

0.37 |

1:1 |

30 |

20 |

||

|

48 |

180 |

0.55 |

1:1 |

30 |

20 |

||

|

ZL15 |

150 |

18 |

180 |

0.25 |

1:1 |

30 |

20 |

|

24 |

180 |

0.37 |

1:1 |

30 |

20 |

||

|

36 |

180 |

0.55 |

1:1 |

30 |

20 |

||

|

48 |

180 |

0.75 |

1:1 |

30 |

20 |

||

|

ZL20 |

200 |

18 |

180 |

0.37 |

1:1 |

40 |

29 |

|

24 |

180 |

0.55 |

1:1 |

40 |

30 |

||

|

36 |

180 |

0.75 |

1:1 |

40 |

34 |

||

|

48 |

180 |

1.1 |

1:1 |

40 |

35 |

||

|

ZL30 |

300 |

18 |

180 |

0.55 |

1:1 |

40 |

30 |

|

24 |

180 |

0.75 |

1:1 |

40 |

34 |

||

|

36 |

180 |

1.1 |

1:1 |

40 |

35 |

||

|

48 |

180 |

1.5 |

1:1 |

40 |

35 |

||

|

ZL45 |

450 |

18 |

1300 |

0.75 |

1:1 |

50 |

45 |

|

24 |

1300 |

1.1 |

1:1 |

50 |

45 |

||

|

36 |

1300 |

1.5 |

1:1 |

50 |

45 |

||

|

48 |

1300 |

2.2 |

1:1 |

50 |

45 |

||

|

ZL60 |

600 |

18 |

1300 |

1.1 |

1:1 |

50 |

45 |

|

24 |

1300 |

1.5 |

1:1 |

50 |

45 |

||

|

36 |

1300 |

2.2 |

1:1 |

50 |

45 |

||

|

48 |

1300 |

3 |

1:1 |

50 |

45 |

||

|

ZL90 |

900 |

18 |

5500 |

1.5 |

1:4 |

60 |

62 |

|

24 |

5500 |

2.2 |

1:4 |

60 |

62 |

||

|

36 |

5500 |

3 |

1:4 |

60 |

62 |

||

|

48 |

5500 |

4 |

1:4 |

60 |

62 |

||

|

ZL120 |

1200 |

18 |

5500 |

2.2 |

1:4 |

60 |

63 |

|

24 |

5500 |

3 |

1:4 |

60 |

63 |

||

|

36 |

5500 |

4 |

1:4 |

60 |

63 |

||

|

48 |

5500 |

5 |

1:4 |

60 |

63 |

Note: The above parameters are for normal supply. If you have special requirements, please indicate them when ordering.

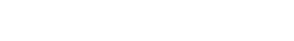

ZL electric actuator dimensions

|

Model |

L |

L1 |

H |

H1 |

F |

F Intelligent |

D |

|

ZL 05-15 |

430 |

252 |

230 |

97 |

159 |

227 |

298 |

|

ZL 20-30 |

443 |

252 |

250 |

97 |

159 |

227 |

298 |

|

ZL 45-60 |

520 |

330 |

300 |

150 |

250 |

318 |

395 |

|

ZL 90-120 |

670 |

460 |

430 |

270 |

450 |

518 |

550 |

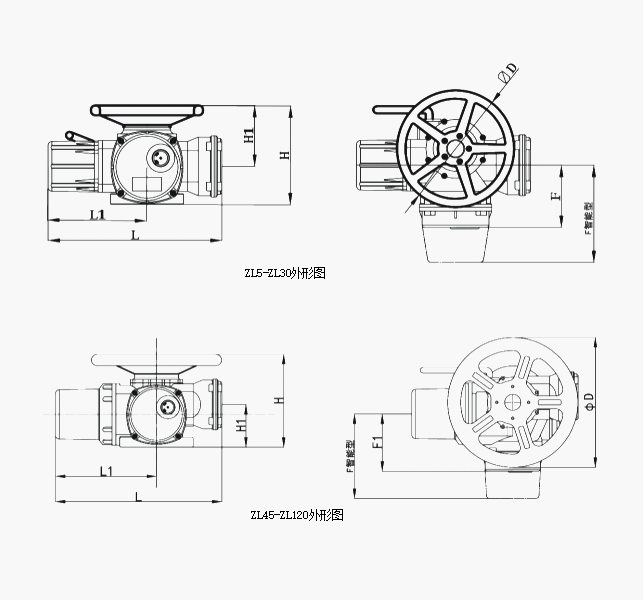

Flange structure and connection dimensions

ZL actuator interface dimensions (torque type)

|

Actuator Model |

Flange Model |

Actuator output interface size details ( Torque type JB 292 0) |

||||||||||

|

D |

D1 |

D2 |

d1 |

d2 |

nd |

b |

Screw hole direction |

h |

h1 |

h2 |

||

|

Z L 05 Z L 10 Z L 15 |

2 Ⅰ |

115 |

95 |

75 |

26 |

39 |

4-M8 |

20 |

45° |

6 |

2 |

5 |

|

2 |

145 |

120 |

90 |

30 |

45 |

4-M10 |

20 |

45° |

8 |

2 |

5 |

|

|

ZL20 ZL30 |

3 Ⅰ |

145 |

120 |

90 |

30 |

45 |

4-M10 |

20 |

45° |

8 |

2 |

5 |

|

3 |

185 |

160 |

125 |

42 |

58 |

4-M12 |

20 |

45° |

10 |

2 |

5 |

|

|

Z L 45 Z L 60 |

4 |

225 |

195 |

150 |

52 |

68 |

4-M16 |

27 |

45° |

12 |

2 |

5 |

|

Z L 90 Z L 120 |

5 Ⅰ |

225 |

195 |

150 |

52 |

68 |

4-M16 |

27 |

45° |

12 |

2 |

5 |

|

5 |

275 |

235 |

180 |

62 |

80 |

4-M20 |

40 |

45° |

14 |

2 |

5 |

|

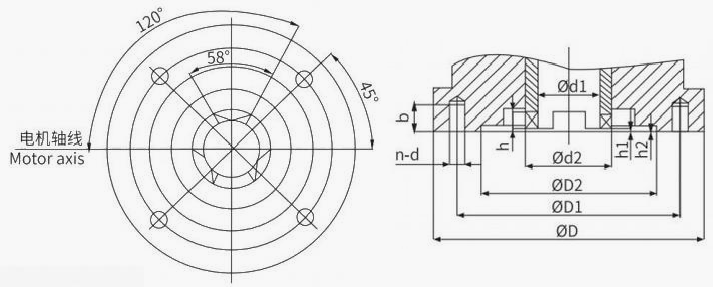

ZL actuator interface dimensions (thrust type)

|

Actuator Model |

Flange Model |

Actuator output interface size details (Thrust type GB12222) |

||||||||

|

D |

D1 |

D2 |

d1 Trapezoidal thread (max) |

nd |

b |

Screw hole direction |

h |

L |

||

|

ZL05 / ZL10 /Z15 ZL10 Z L 15 |

F10 |

125 |

102 |

70 |

Tr28 |

4-M10 |

16 |

45° |

3 |

40 |

|

ZL20 / ZL30 |

F14 |

175 |

140 |

100 |

Tr36 |

4-M16 |

25 |

45° |

4 |

55 |

|

ZL45 / ZL60 |

F16 |

210 |

165 |

130 |

Tr44 |

4-M20 |

35 |

45° |

5 |

70 |

|

ZL90 / ZL120 |

F25 |

300 |

254 |

200 |

Tr60 |

8-M16 |

30 |

22.5° |

4 |

90 |

русский

русский Español

Español